Products

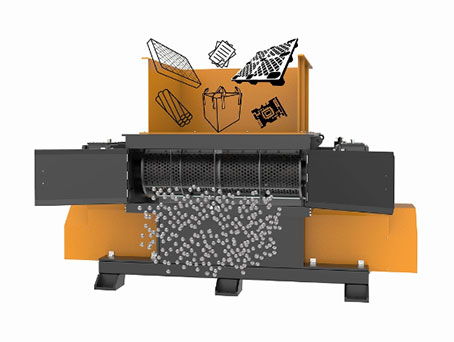

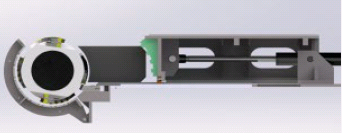

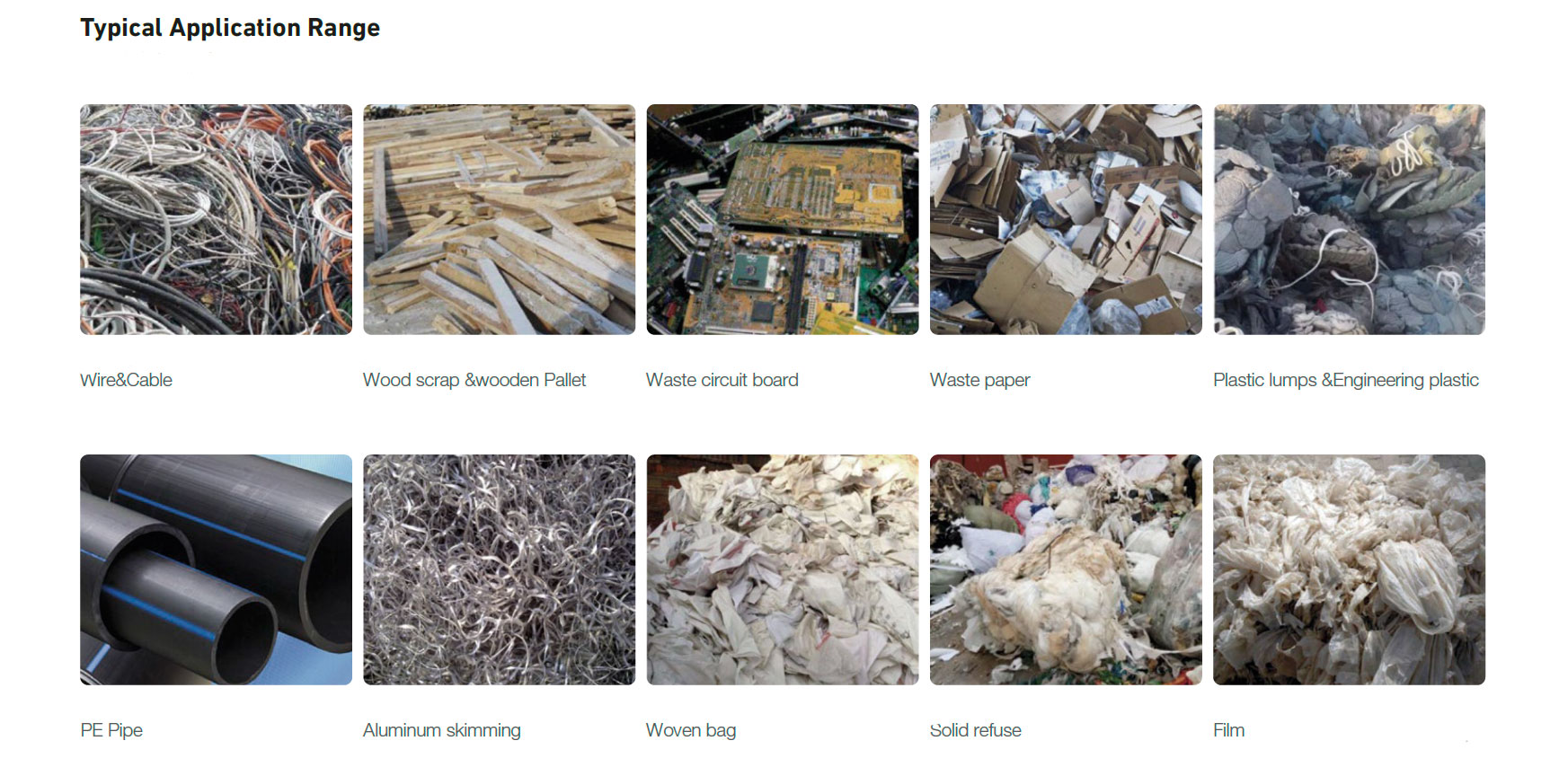

DZ series single shaft shredder is a crushing machine with perfect design. It's widely used and qualified to shred various waste materials such as plastic block, pipe, film, cable, wood, paper and so on.

The suitable screen can be chosen according to the materials and the next processing requirements. The output material could be directly reused or further shred into smaller pieces.

Smart electric keeps shredder safe, equipped with SIEMENS, SCHNEIDER and other famous brand.

E-mail: joyal@crusherinc.com

| Model | DZ 650 | DZ 900 | DZ 1100 | DZ 1400 | DZ 1600 | DZ 2100 | DZ 2500 |

| Rotation diameter (mm) | Φ240 | Φ400 | Φ400 | Φ400 | Φ480 | Φ480 | Φ560 |

| Main shaft speed (rpm) | 73 | 73 | 73 | 73 | 73 | 73 | 90 |

| Pushing chamber route (mm) | 520 | 820 | 820 | 820 | 1000 | 1000 | 1200 |

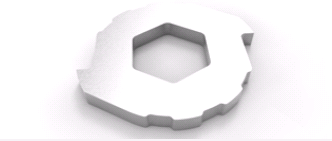

| Number of rotor blades (pcs) | 26+2 | 52+2 | 66+2 | 80+2 | 94+2 | 122+23+2 | 150+28+2 |

| Number of rotor blades (pcs) | 2\4 | 3\6 | 4\8 | 5\10 | 6\12 | 8\16 | 6\12 |

| Crushing chamber(mm) | 550*650 | 840*900 | 840*1130 | 840*1360 | 1020*1600 | 1020*2050 | 1220*2510 |

| Screen diameter(mm) | Φ15-60 | Φ25-80 | Φ25-100 | Φ25-00 | Φ40-100 | Φ40-150 | Φ40-150 |

| Motor power(kw) | 22+1.5 | 55+2.2 | 75+5.5 | 90+5.5 | 75*2+5.5 | 90*2+11 | 110*2+11 |

| Dimension size(mm) | 1800*1400*1750 | 2750*2300*2350 | 2750*2650*2350 | 2750*2900*2350 | 3500*4200*2600 | 4800*4800*3000 | 4800*5200*3200 |

| Feeding size(mm) | 850*1100 | 1250*1300 | 1250*1500 | 1250*1700 | 1500*2000 | 1500*2500 | 1500*3000 |

| discharge height(mm) | 460 | 810 | 810 | 810 | 900 | 1000 | 1200 |

| Weight(kg) | 1750 | 4800 | 5400 | 6300 | 12000 | 16000 | 21000 |

+8613795207229

E-mail Address

joyal@crusherinc.com

Sales Hotline

+86-21-68763311

Company Address

No.365, Chuanhong Road, Shanghai, China

©2025 Shanghai Joyal Machinery Co., Ltd. All Rights Reserved.