Products

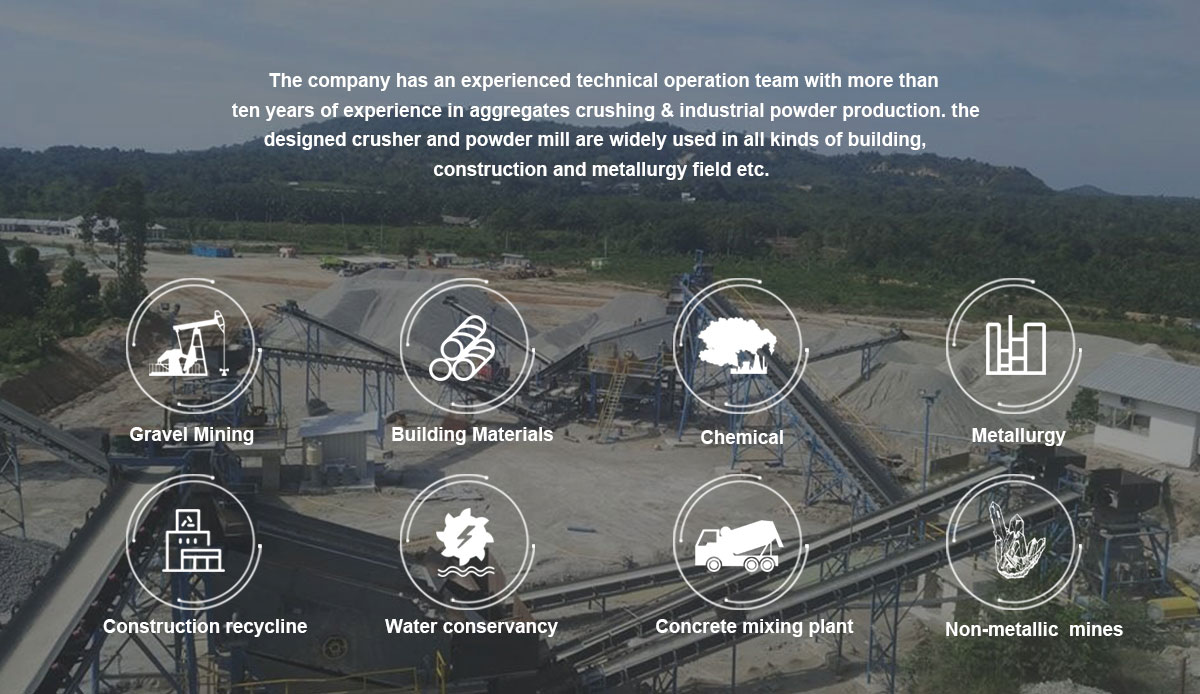

The JOYAL VSI Sand Making Machine is improved on the basis of Germany high technology, which is highly-efficient and superior in performance. The JOYAL VSI Crusher (sand making machine) is widely used to produce sand and stone for highway, high-speed railway, city project, hydropower dam constructions, and concrete mixing plant, and it’s also widely used in sand making and stone reshaping industry.

Applications: VSI sand making machine is used for highway, high-speed railway, high-rise building, municipal engineering, hydropower dam construction, concrete mixing station to produce sand and gravel aggregate, and it is the equipment in the field of artificial sand making and stone shaping.

E-mail: joyal@crusherinc.com

1. Central feeding:Raw materials fall down into the feeding hopper, then enters the impellor through central entrance inlet, thus the material being accelerated by the high-speed impellor and being thrown out at the speed of 60-75m/s. It is crushed when hitting the impact plate, and the end products comes out from the discharging outlet.

2. Ring feeding:Raw materials fall down into the feeding hopper, and the materials are divided into two parts by a special plate. Some materials enter the impellor through the center of the plate and the other part of materials falls down from outside of the plate. The materials thrown out earlier crush the materials down from outside, thus the materials crushed and re-crushed.

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | ||

|

Throughput (t/h) |

Center and Sides Feeding | 120-180 | 200-260 | 300-380 | 450-520 | |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | ||

| Max. Feeding Size (mm) | Soft Material | 35 | 40 | 45 | 50 | |

| Hard Material | 30 | 35 | 40 | 45 | ||

| Rotation Speed(rpm) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | ||

| Double Motor Power (kw) | 110 | 180 | 264 | 400 | ||

|

Overall Dimension L×W×H (mm) |

3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5000×2700×3300 | ||

| Weight (t) | 7.8 | 10.3 | 16 | 25.6 | ||

| Vibrating Sensor | Inspection Range: 0.1-20mm/s Continual Adjustment | |||||

| Hydraulic Oil Pump | Motor Power of Double Oil Pump(Kw) | 2×0.31kw | ||||

|

Overall Dimension L×W×H (mm) |

820×520×1270 | |||||

| Power of Oil Tank Heater | 2KW | |||||

+8613795207229

E-mail Address

joyal@crusherinc.com

Sales Hotline

+86-21-68763311

Company Address

No.365, Chuanhong Road, Shanghai, China

©2025 Shanghai Joyal Machinery Co., Ltd. All Rights Reserved.