Products

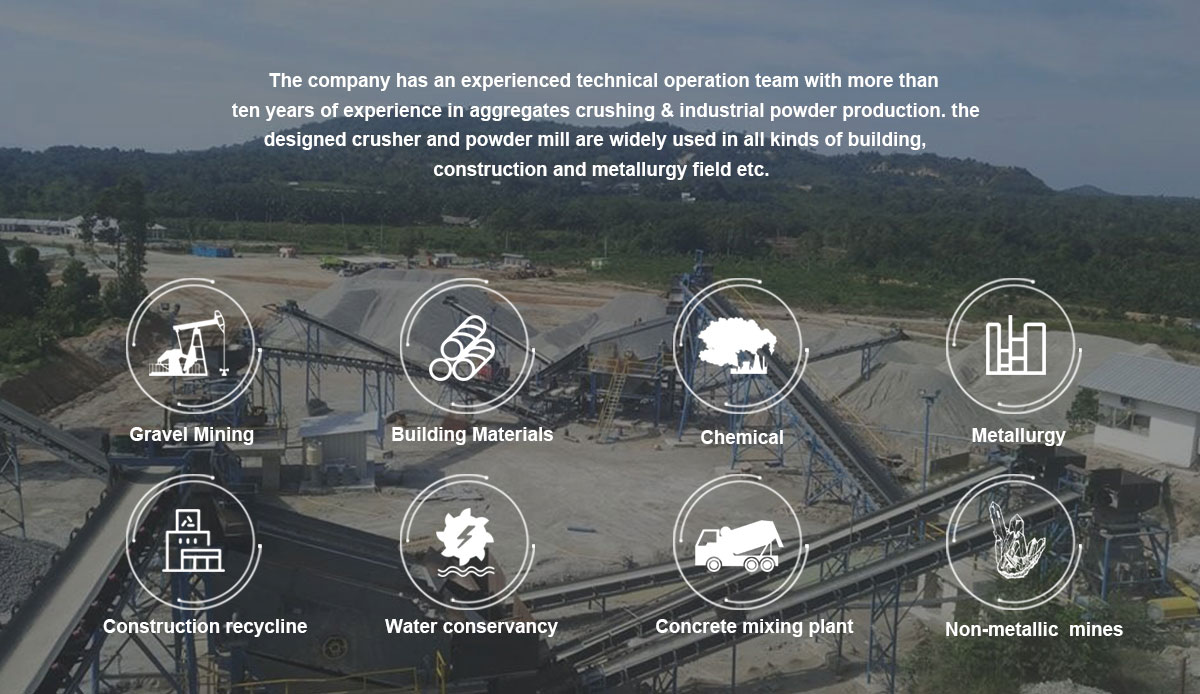

Applications:

E-mail: joyal@crusherinc.com

The crushing method of PEV series jaw crusher is curved extrusion type. When working, the motor drives the pulley, and swings up and down through the eccentric shaft, and when the movable jaw rises, the movable jaw plate approaches the fixed jaw plate, and at the same time the material is crushed by multiple crushing, such as extrusion, rubbing, and rolling; When the moving jaw goes down, the moving jaw leaves the fixed jaw plate under the action of the return spring, and the broken material is freely discharged from the discharge port under the action of gravity. With the continuous transmission of the motor to crush the motorized jaw for periodic crushing and discharging, mass production is realized.

| Model | Max.feeding size (mm) | discharge adjusting size (mm) | Capacity (t/h) | Motor (kW) |

Dimension size (L×W×H)(mm) |

Weight (t) |

| PEV500×750 | 425 | 45-150 | 45-107 | 45-55 | 3100×1980×2290 | 12 |

| PEV600×900 | 510 | 75-180 | 100-200 | 55-75 | 3450×2360×2780 | 17 |

| PEV750×1100 | 640 | 80-190 | 140-320 | 90-110 | 3750×2580×3180 | 26 |

| PEV860×1100 | 730 | 100-200 | 200-500 | 110-132 | 4870×2850×3170 | 32 |

| PEV900×1200 | 760 | 100-220 | 220-600 | 110-132 | 3500×2850×3290 | 48 |

| PEV1000×1200 | 850 | 150-300 | 280-750 | 132-160 | 4700×2930×3460 | 52 |

+8613795207229

E-mail Address

joyal@crusherinc.com

Sales Hotline

+86-21-68763311

Company Address

No.365, Chuanhong Road, Shanghai, China

©2025 Shanghai Joyal Machinery Co., Ltd. All Rights Reserved.