Products

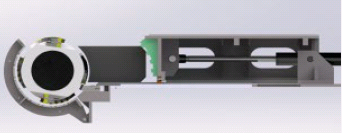

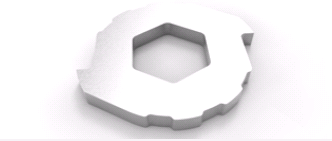

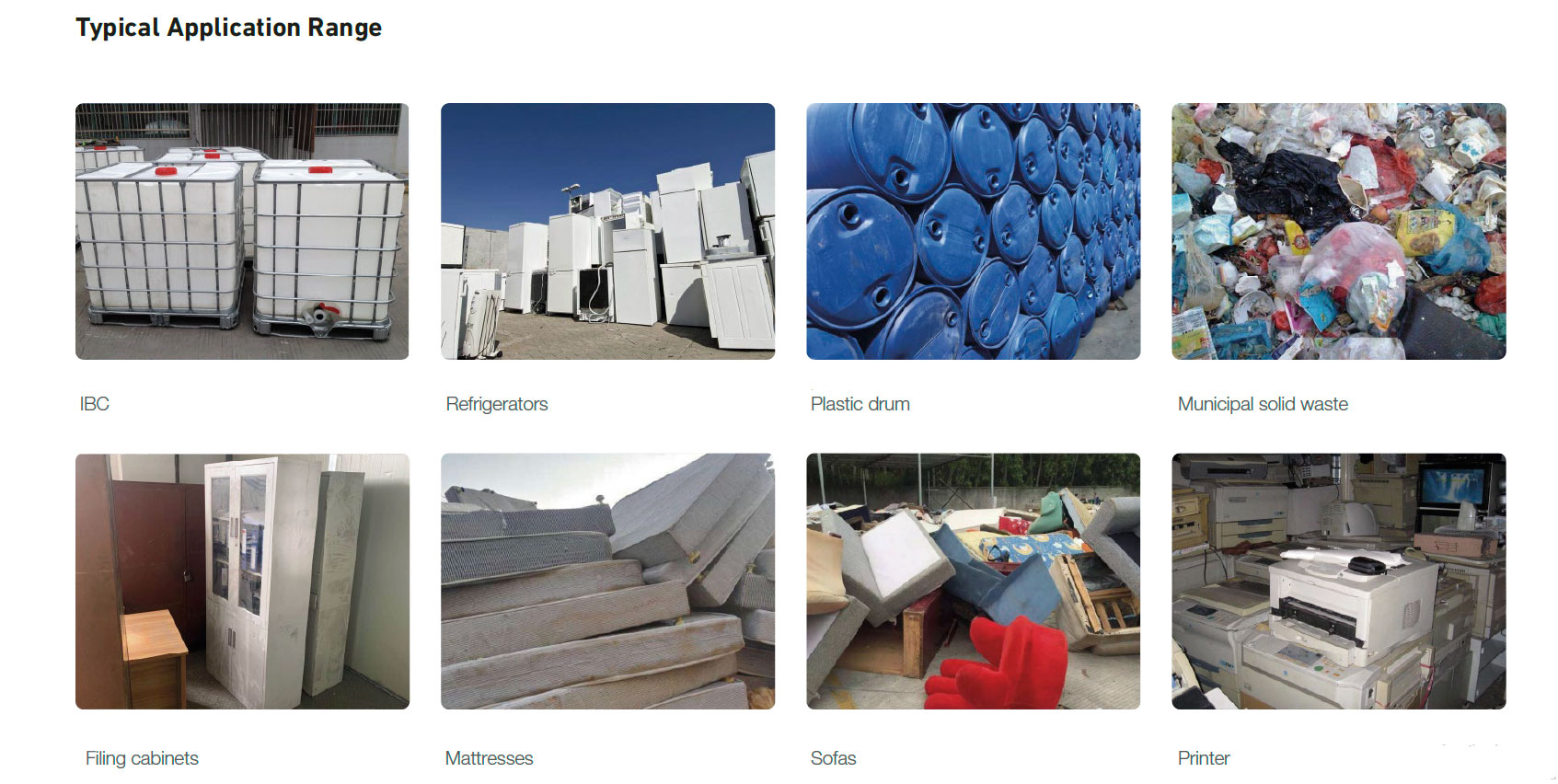

FZ series shredders have various functions and advantages.They fit for shredding plastic drums,plastic bottles,household waste,Hazardous waste materials etc...

The bottom of the shredder can be equipped with a screen according to customer requirements,it can control the discharge material size in order to meet customer’ s subsequent use.

The reducer and spindle are connected by German standard DIN5480, it has features of simple dis-assembly, large and stable transmission torque, safe and reliable operation.

The main electric parts adopt the international brand such as Schneider,Siemens and ABB,so as to ensure the stable operation of the shredding system.

E-mail: joyal@crusherinc.com

| Model | Blade diameter (mm) | Main shaft speed (rpm) | Blade thickness (mm) | Blade quantity (pcs) | Cutting chamber (mm) | Motor power (kw) | Dimension(mm) | Weight(kg) |

| FZ 9080 | Φ290 | 15~25 | 25 | 32*2 | 900*800 | 18.5*2 | 2400*1550*2500 | 4700 |

| FZ 90100 | Φ290 | 15~25 | 25 | 40*2 | 900*1000 | 18.5*2 | 2600*1550*2500 | 5000 |

| FZ 100100 | Φ320 | 15~25 | 40 | 25*2 | 1000*1000 | 22*2 | 2900*1700*2800 | 6600 |

| FZ 100120 | Φ320 | 15~25 | 40 | 30*2 | 1000*1200 | 22*2 | 3100*1700*2800 | 7100 |

| FZ 100140 | Φ320 | 15~25 | 40 | 35*2 | 1000*1400 | 22*2 | 3300*1700*2800 | 7600 |

| Model | Blade diameter (mm) | Main shaft speed (rpm) | Blade thickness (mm) | Blade quantity (pcs) | Cutting chamber (mm) | Motor power (kw) | Dimension(mm) | Weight(kg) |

| FZ 130120 | Φ430 | 10~15 | 50 | 24*2 | 1300*1200 | 30*2+15*2 | 4100*2000*3100 | 15600 |

| FZ 130140 | Φ430 | 10~15 | 50 | 28*2 | 1300*1400 | 30*2+15*2 | 4300*2000*3100 | 16000 |

| FZ 130160 | Φ430 | 10~15 | 50 | 32*2 | 1300*1600 | 30*2+15*2 | 4500*2000*3100 | 17000 |

| FZ 160160 | Φ510 | 10~15 | 50 | 32*2 | 1600*1600 | 45*2+30*2 | 4800*2300*3600 | 22500 |

| FZ 160180 | Φ510 | 10~15 | 50 | 36*2 | 1600*1800 | 45*2+30*2 | 5000*2300*3600 | 23700 |

| FZ 160200 | Φ510 | 10~15 | 50 | 40*2 | 1600*2000 | 45*2+30*2 | 5200*2300*3600 | 25000 |

+8613795207229

E-mail Address

joyal@crusherinc.com

Sales Hotline

+86-21-68763311

Company Address

No.365, Chuanhong Road, Shanghai, China

©2025 Shanghai Joyal Machinery Co., Ltd. All Rights Reserved.