Products

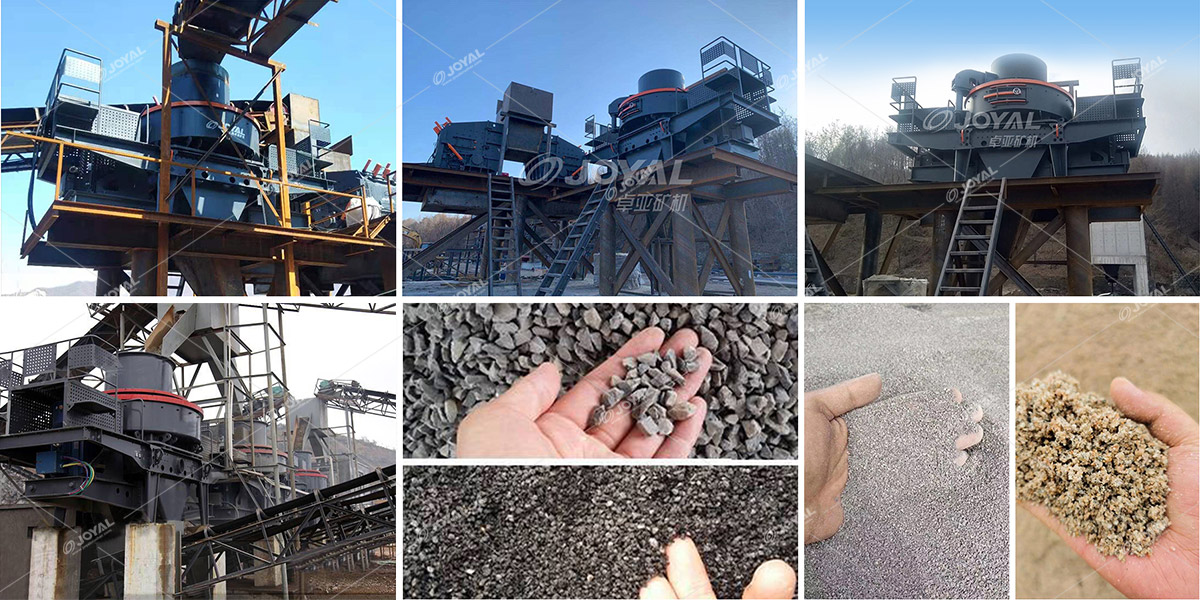

VSI5X series new sand making machine (centrifugal impact crusher) is suitable for medium and fine crushing all kinds of ores and rocks with different hardness such as bauxite quartz sand oxide perlite basalt and other high hardness materials.

Applications: VSI5X Sand Maker is the core equipment in machine-made sand industry.

E-mail: joyal@crusherinc.com

VSI5X Vertical-shaft Impact Crusher (also known as "Sand Maker") has two feed modes – "feed at center" and "feed at center & sides". As for the former mode "feed at center", materials at the feed hopper firstly pass through the central hole into the high-speed spinning rotor. In the rotor, materials are fully accelerated and thrown outwards from the launching port to collide with a part of materials that freely fall after rebound. Next, materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening. As for the latter mode "feed at center & sides", firstly, materials at the feed hopper pass through the circular hole. Then, materials are divided into two parts by the distributing tray. One part of materials enter the high-speed rotating impeller while the other part of materials fall from all sides of the tray. Materials in the impeller would be accelerated rapidly and thrown outwards at a high speed to collide with materials falling from all sides of the tray. Next, all materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening.

| Model | VSI5X-7615 | VSI5X-8522 | VSI5X-9532 | VSI5X-1145 | |

| Maximum feeding size (mm) | Soft material | 35 | 40 | 45 | 50 |

| Hard material | 30 | 35 | 40 | 45 | |

| Throughput (t/h) | Side and central feeding | 150-280 | 240-380 | 350-540 | 500-640 |

| Fully central feeding | 70-140 | 120-190 | 180-280 | 250-360 | |

| Speed (r/min) | 1700~1900 | 1500~1700 | 1300~1510 | 1100~1310 | |

| Power (kW) | 75×2 | 110×2 | 160×2 | 220×2 | |

| Overall dimension (mm) | 4100×2330×2300 | 4140×2500×2700 | 4560×2600×2900 | 5100×2790×3320 | |

+8613795207229

E-mail Address

joyal@crusherinc.com

Sales Hotline

+86-21-68763311

Company Address

No.365, Chuanhong Road, Shanghai, China

©2025 Shanghai Joyal Machinery Co., Ltd. All Rights Reserved.